Groundwater remediation of an LCKW damage in Bonn, Bad-Godesberg

Project details

CONTRACTOR:

TURNED AND MASS-PRODUCED PARTS LUBIG GMBH & CO. KG

PROJECT IMPLEMENTATION AND PLANNING:

DIPL.-GEOL. CHRISTOPH RICHTER, M.SC. K. HERPERS (MULL AND PARTNER HAGEN)

PERFORMANCE PERIOD:

SINCE 2011

REGULATORY/SPECIALIST AUTHORITIES:

BUNDESSTADT BONN, OFFICE FOR THE ENVIRONMENT, CONSUMER PROTECTION AND LOCAL AGENDA

BUSINESS AREA:

ENVIRONMENTAL AND GEOTECHNICAL ENGINEERING

LOWER:

HAGEN

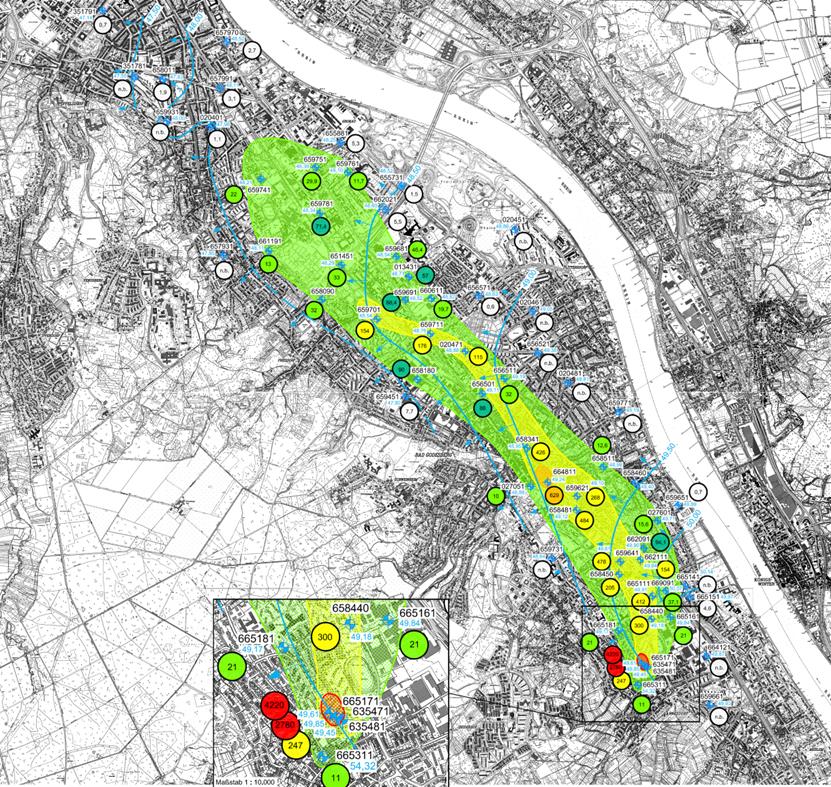

SCHThe former production site of Lubig GmbH is located in the Bad-Godesberg district of Bonn. Precision turned parts were produced. TCE was used as a degreasing agent for metalworking. In addition, MKW was used in the machining process. Handling losses and the entry points responsible for a large number of CHC damages at canal bottom fractures or canal shafts led here to a large-scale CHC damage in the groundwater with a plume length of up to 7 km. The plume extends from the south near Bad Godesberg to the southern city centre of Bonn. The longitudinal extension runs parallel to the overriding receiving watercourse (Rhine). Besides the direct proximity to the Rhine with complex hydraulic conditions due to Rhine floods and their dispersive influences in the Quaternary aquifer, the geo- and hydrogeological site conditions are characterised by further loose rock deposits of the Middle Terrace as well as lateral alluvial fan sediments in the upper pore aquifer. The underlying fissured aquifer is also affected by the LCKW contamination. The fissure groundwater feeds the lower terrace with groundwater and thus leads to a permanent supply or base load of CFCs in the pore aquifer. Assets worthy of protection, such as the two medicinal springs in the Bad Godesberg area, are located about 1.5 km away. In addition, emergency drinking water wells are located in the damage plume area, which had to be taken into account in the RIA. In the course of extensive preliminary investigations between 2006 and 2011, considerable soil, soil air and groundwater contamination by CFCs was detected. During the investigations, a wide variety of investigation methods were used to increase the informative value of the origin and extent of the damage, such as MIP soundings, stratified measuring point construction, etc. The results of these investigations were used to determine the extent of the damage. Isotope investigations were used, among other things, to clarify the cause as well as to investigate the degradation. Up to approx. 5,700 mg/kg LCKW and up to 74,000 mg/kg MKW were recorded in the soil and in the soil air up to approx. 4,300 mg/m³. In the groundwater, CHC levels of up to 35,000 µg/l were detected in the central downstream. Further groundwater investigations revealed the above-mentioned pronounced damage plume in the urban area. A groundwater model from our company was used to calculate the remediation capability and the remediation period of the groundwater damage - in particular for the damage plume. A remediation period of 15 years was forecast to achieve the remediation targets in the defined balance sheet levels I and II. From 2011 to 2016, M&P carried out extensive remediation investigations with the aim of completely demolishing the existing buildings and remediating the source term. A deconstruction and reuse concept and a remediation plan for the soil on the site (approx. 7,600 m²) and the groundwater were carried out. Already in 2017, a groundwater remediation system using p&t was installed in the direct downstream after prior tendering by our office and operated since September 2017. Since late spring 2018, deconstruction and soil/source term remediation has been taking place at the site. The groundwater downstream is currently additionally secured at the property boundary via a well gallery. The damage plume is secured via the well gallery in the direct downstream.

The following measures were planned to achieve the objective:

- Complete deconstruction of the existing production halls incl. deep debris removal and existing residential buildings.

- Swelling term remediation in unconsolidated rock

- Groundwater outflow protection at the property boundary by means of a well gallery, protection of the damage plume by means of a groundwater remediation system, purification of the extracted water via three activated carbon filters and re-infiltration of the completely purified water into the groundwater aquifer, planned duration approx. 15 years.

The following services were provided by Mull und Partner Ingenieurgesellschaft mbH:

- Extensive remediation investigations on the site

- Planning of soil remediation as off-site source term remediation on the site

- Groundwater flow and solute transport model

- Development of a remediation plan according to § 13 BBodSchG

- Planning of the groundwater remediation system

- Development of the deconstruction and utilisation concept for the deconstruction of the standing halls as well as the adjacent residential buildings

- Preparation of the tender documents for the deconstruction and soil remediation works / preparation of and participation in the award of contracts

- Execution of expert supervision, local construction supervision, construction management and project management for the groundwater remediation plant (since 2017), monitoring of the remediation plant, plume monitoring

- Execution of the expert supervision and support of the local construction supervision for the deconstruction and soil remediation (summer / autumn 2018)

The remediation plan was professionally reviewed and approved by various official institutions in NRW (AAV NRW, LANUV NRW, District Government of Cologne, City of Bonn) as well as an external supervisor. The background to this elaborate examination procedure was the elaboration of remediation target values related to the specific case and pointing the way. The damage case including the site-specific remediation target was presented at training events in 2017.