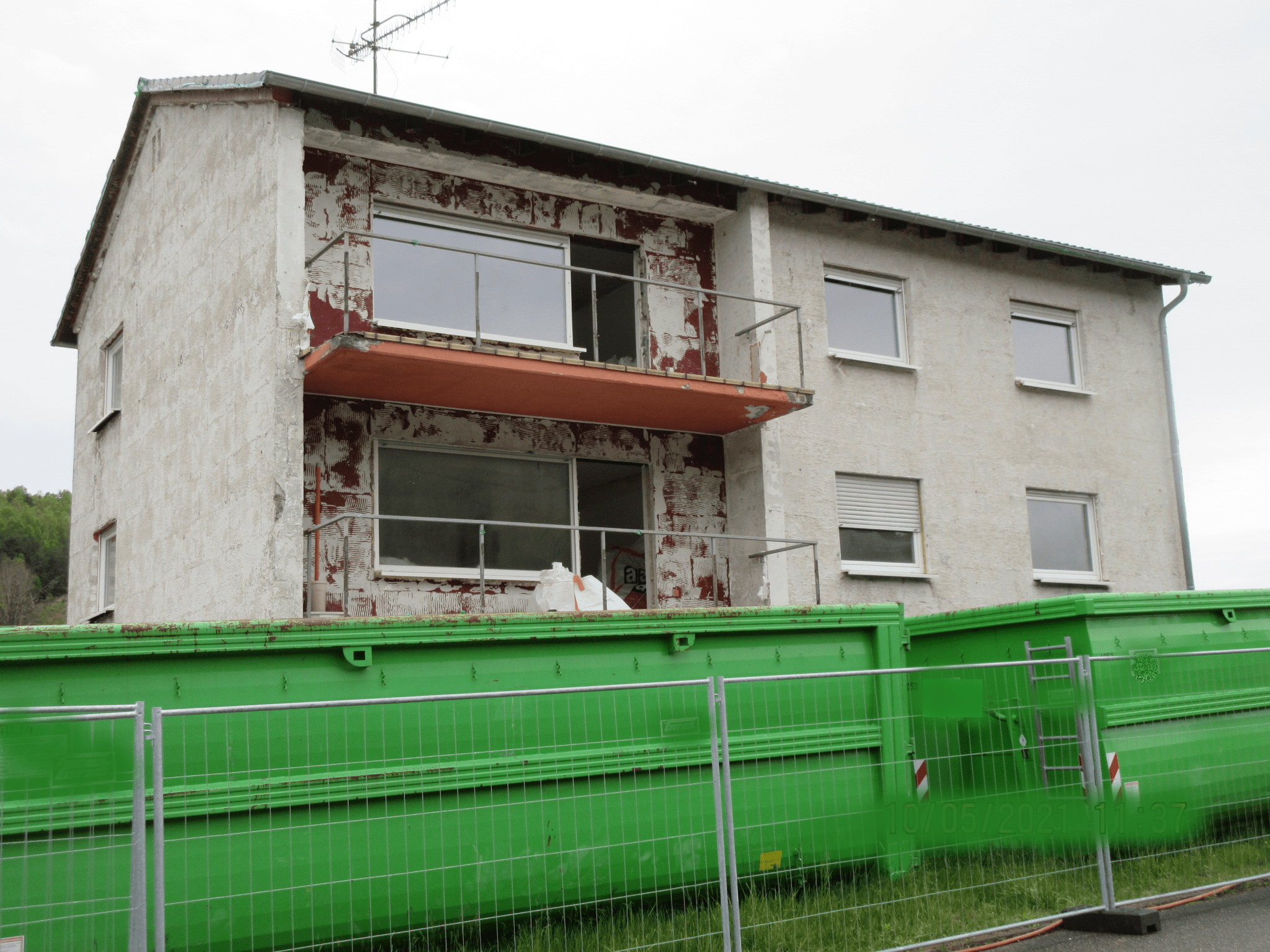

In Pirmasens, the demolition of a former residential building on the premises of a building materials company was planned on behalf of the property owner. During the preliminary waste investigations, the visually inconspicuous plaster on the EPS thermal insulation composite system was found to contain asbestos. The adhesive batches of the EPSW boards were also identified as being contaminated with asbestos fibres. Such findings have been found more frequently recently.

As part of the tendering process, the special occupational health and safety and emission protection measures were defined in consultation with the competent authority at SGD Süd (Struktur und Genehmigungsdirektion Süd) and the suitability of the potential bidders was checked.

For the removal of the outer envelope, the building was provided with a planked scaffold, access to the work area was through an airlock where protective clothing was donned and doffed. A negative-pressure holding device (UHG) connected to the interior of the abatement scaffolding captured the asbestos fibres released during plaster removal and fed them to a filter system. After completion of the work, the entire work area was cleaned with special hoovers and sprayed with fibre binder. Subsequently, room air tests for asbestos fibres confirmed the success of the cleaning measures.

After the scaffolding was dismantled, the building was mechanically demolished and the demolition waste was disposed of so that the construction site could be prepared for the subsequent construction of a storage area.